Green Chemistry

GREEN CHEMISTRY is a chemical philosophy encouraging the design of products and processes that reduce or eliminate the use and generation of hazardous substances. From a chemical perspective, the earth supplies raw mineral materials at equilibrium with the environment. Upon chemical or mechanical processing for purity and formulation, most substances become unstable, while striving to return to their simpler balanced chemical formation. This cyclical process comes full cycle when it chemically returns to its natural more stable form.

GREEN CHEMISTRY is a chemical philosophy encouraging the design of products and processes that reduce or eliminate the use and generation of hazardous substances. From a chemical perspective, the earth supplies raw mineral materials at equilibrium with the environment. Upon chemical or mechanical processing for purity and formulation, most substances become unstable, while striving to return to their simpler balanced chemical formation. This cyclical process comes full cycle when it chemically returns to its natural more stable form.

Mineral Life Int’l products originate from mineral sources, are based on geological processes, and create long lasting and environmentally friendly surfaces for architecture. Much of our raw materials are derived from recycled sources, as well as utilizing “food grade” chemical additives. We strive to follow the twelve principles of Green Chemistry.

The Twelve Principles

The design of environmentally benign products and processes may be guided by the 12 Principles of Green Chemistry, listed below. These principles are a categorization of the fundamental approaches taken to achieve the goal of pollution prevention, and have been used as guidelines and design criteria by molecular scientists (Anastas & Kirchhoff, 2002).

1. Prevention: It is better to prevent waste than to treat or clean up waste after it has been created.

2. Atom economy: Synthetic methods should be designed to maximize the incorporation of all materials used in the process into the final product.

3. Less hazardous chemical syntheses: Wherever practicable, synthetic methods should be designed to use and generate substances that possess little or no toxicity to human health and the environment.

4. Designing safer chemicals: Chemical products should be designed to affect their desired function while minimizing their toxicity.

5. Safer solvents and auxiliaries: The use of auxiliary substances (solvents, separation agents, etc.) should be made unnecessary wherever possible and innocuous when used.

6. Design for energy efficiency: Energy requirements of chemical processes should be recognized for their environmental and economic impacts and should be minimized. If possible, synthetic methods should be conducted at ambient temperature and pressure.

7. Use of renewable feedstocks: A raw material or feedstock should be renewable rather than depleting whenever technically and economically practicable.

8. Reduce derivatives: Unnecessary derivatization (use of blocking groups, protection/deprotection, and temporary modification of physical/chemical processes) should be minimized or avoided if possible, because such steps require additional reagents and can generate waste.

9. Catalysis: Catalytic reagents (as selective as possible) are superior to stoichiometric reagents.

10. Design for degradation: Chemical products should be designed so that at the end of their function they break down into innocuous degradation products and do not persist in the environment.

11. Real-time analysis for pollution prevention: Analytical methodologies need to be further developed to allow for real-time, in process monitoring and control prior to the formation of hazardous substances.

12. Inherently safer chemistry for accident prevention: Substances and the form of a substance used in a chemical process should be chosen to minimize the potential for chemical accidents, including releases, explosions, and fires.

The following mineral classes and terms represent raw materials utilized for Mineral Life Int’l product development:

Silicate Waterglass

Silicate compounds are not only important basic constituents of minerals, they have performed the role of binders in the majority of sedimentary rocks.

Silicate compounds are not only important basic constituents of minerals, they have performed the role of binders in the majority of sedimentary rocks.

Silicate binders were used by the ancient Egyptians.

It has been estimated that some 6000 years ago sodium (and possibly also potassium) silicates were produced for the first time by melting together quartz sand and naturally occurring soda ash or potash gained from combustion processes. In Germany, they began to be used as binders in wall paints about 150 years ago. Today, modern, eco friendly, silicate-based coating systems are an indispensable tool for professionals in the building paints and plasters industry. They are able to meet the high requirements of architects, artisans and building owners.

Today, modern, eco friendly, silicate-based coating systems are an indispensable tool for professionals in the building paints and plasters industry. They are able to meet the high requirements of architects, artisans and building owners.

Silicate Paint has the following significant advantages:

- Ready to use, excellent shelf life

- Good application properties on most substrates

- Open-pored coating, hence good steam permeability

- Good color stability

- Harmonious, matte surface appearance

- Low tendency to soil, self-cleaning properties

- High durability, hence very efficient

- No preservation required to ensurestorability

- Silicate binders do not cause allergies

- Suitable for indoor and outdoor applications in new and old buildings

- Harmless to the environment

- Natural stone-like finish

Silicates are used as hardeners or densifiers for concrete slab surfaces because of their reaction with the lime content in concrete. This reaction fills and seals the pores of the slab surface with an insoluble calcium silicate. These compounds block the micro pores in concrete with extremely hard silicates. When the surface is polished from usage or with diamond abrasives, a rich deep intrinsic shine is produced.

Lithium Silicates are the most effective hardeners of concrete slab surfaces.

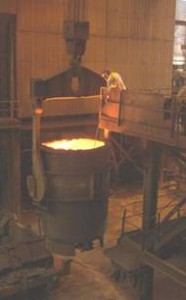

Elemental Iron

Iron is believed to be the sixth most abundant element in the universe. Iron is the most abundant element on Earth. While it makes up only about 5% of the Earth’s crust, the earth’s core is believed to consist largely of a metallic iron-nickel alloy comprising 35% of the mass of the Earth as a whole. Iron is the fourth most abundant element in the Earth’s crust and the second most abundant metal (after aluminum). Most of the iron in the crust is found combined with oxygen as iron oxide minerals such as hematite, magnetite, and taconite. About 5% of the meteorites similarly consist of iron-nickel alloy. Although rare, these are the major form of natural metallic iron on the earth’s surface.

Iron is believed to be the sixth most abundant element in the universe. Iron is the most abundant element on Earth. While it makes up only about 5% of the Earth’s crust, the earth’s core is believed to consist largely of a metallic iron-nickel alloy comprising 35% of the mass of the Earth as a whole. Iron is the fourth most abundant element in the Earth’s crust and the second most abundant metal (after aluminum). Most of the iron in the crust is found combined with oxygen as iron oxide minerals such as hematite, magnetite, and taconite. About 5% of the meteorites similarly consist of iron-nickel alloy. Although rare, these are the major form of natural metallic iron on the earth’s surface.

Iron is also essential for life, as it carries oxygen in the blood throughout the body.

Iron Coating is composed of 100% elemental iron. Through manipulation of processing factors such as pH and oxidation / reduction potential, elemental Iron is made available in a stable, anti-corrosive form, most suitable for our coatings over Concrete and Lime Paint.

Carbon steel corrosion is much more prevalent, because the iron component is not in a stable form. Its severity depends on (among others):

- Conditions (Temperature / Pressure),

- Composition,

- pH, and

- oxidation potential

Copper Copper has played a significant part in the history of humankind, which has used the easily accessible uncompounded metal for thousands of years. Civilizations in places such as Iraq, China, Egypt, Greece, India and the Sumerian cities all have early evidence of using copper. During the Roman Empire, copper was principally mined on Cyprus, hence the origin of the name of the metal as Cyprium, “metal of Cyprus”, later shortened to Cuprum.

Copper has played a significant part in the history of humankind, which has used the easily accessible uncompounded metal for thousands of years. Civilizations in places such as Iraq, China, Egypt, Greece, India and the Sumerian cities all have early evidence of using copper. During the Roman Empire, copper was principally mined on Cyprus, hence the origin of the name of the metal as Cyprium, “metal of Cyprus”, later shortened to Cuprum.

Copper, as native copper, is one of the few metals to naturally occur as an uncompounded mineral. Copper is an essential trace nutrient to all high plants and animals. In animals, including humans, it is found primarily in the bloodstream, as a co-factor in various enzymes, and in copper-based pigments.

Because of copper’s reactivity with Lime in concrete and Lime Paint, we employ it’s usage in Mineral Life Patina Solutions to create verdigris greens such as Jade and Malachite -classic patina colors.

Patina

The term Patina is a coating of various chemical compounds such as oxides or carbonates formed on surfaces during exposure to weathering. The green patina that forms naturally on copper and bronze is known as verdigris and consists of copper carbonate. Patina also refers to accumulated changes in surface texture and color that result from normal use of an object such as a coin or a piece of furniture. Artists and metalworkers often deliberately add patinas as a part of the original design and decoration of art and furniture, or to simulate antiquity in newly made objects.

The term Patina is a coating of various chemical compounds such as oxides or carbonates formed on surfaces during exposure to weathering. The green patina that forms naturally on copper and bronze is known as verdigris and consists of copper carbonate. Patina also refers to accumulated changes in surface texture and color that result from normal use of an object such as a coin or a piece of furniture. Artists and metalworkers often deliberately add patinas as a part of the original design and decoration of art and furniture, or to simulate antiquity in newly made objects.

Figuratively, patina can refer to any fading, darkening or other signs of age, which are felt to be natural and/or unavoidable.

The chemical process by which a patina forms is called patination, and a work of art coated by a patina is said to be patinated.

Mineral Life Patina Solutions are employed for producing patination on concrete or lime painted surfaces. This is possible because these solutions are formulated with iron and copper in the solution itself,thus creating patinas on reaction with the lime content of Lime Paint and Concrete.

Limestone, Calcium Carbonate and Calcium Hydroxide (Lime)

Limestone is a sedimentary rock composed largely of the mineral calcite (CaCO3), calcium carbonate.

Limestone is a sedimentary rock composed largely of the mineral calcite (CaCO3), calcium carbonate.

Calcium carbonate is a common substance found as rock in all parts of the world, and is the main component of shells of marine organisms, snails, and eggshells.

Another form is that of oolites (oolitic limestone) which can be recognized by its granular appearance. Limestone makes up about 10% of the total volume of all sedimentary rocks.

Calcium hydroxide, traditionally called slaked lime or hydrated lime, is a chemical with the chemical formula Ca(OH)2 . It is a colorless crystal or white powder, and is obtained when calcium oxide (called lime or quicklime) is mixed, or “slaked” with water.